M anagement System

anagement System

ISO 9001:2015

ISO 14001:2015

Marshallstraat 18c, 5705 CN Helmond

Tel:+31-655701610

soldersolutions@ishikawa-europe.com

Home > Lead-free (EVASOL) > [Solder paste (bottle)] Printing type for LASER 8229 series

Suitable for LASER heat soldering.Achieve good soldering quality, despite the rapid heating.

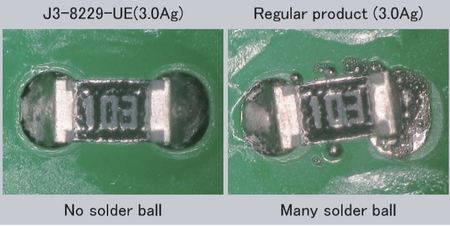

●Thermal shock test(QFP shoot in transmitted light)

Few solder ball occurs by rapid heating in short time

Irradiation time:0.2 sec

Parts:1005R chip

Irrdiation method:Radiate the entire chip and pad

Enable to adopt into general use printer for SMT.No special printer is required

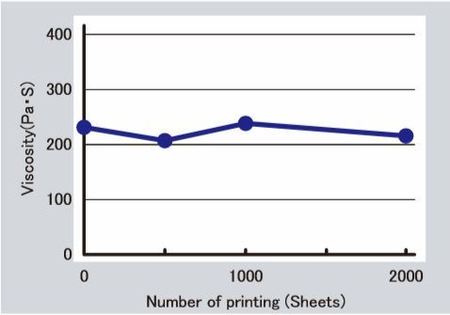

●Viscosity test of cotinuous printing

Stable viscosity of continuous printing

Enable to adopt brand-new process combined LASER and printer which can shorten the SMT processing time as reflow oven is not required.

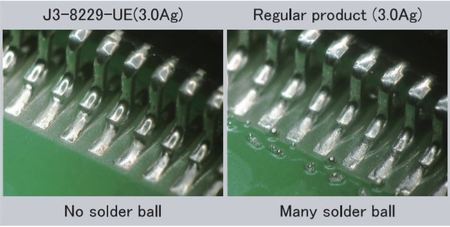

●LASER SMT test of QFP parts

Enables combine to printing, suitable for various SMT parts

Irradiation:5 sec/25pins

Parts:0.5mm pich QFP

Irradiation method:Scan irradiation to leads and pads

| Alloy type | J3 (Sn:Bal / Ag 3.0 / Cu 0.5) R4 (Sn:Bal / Ag 0.3 / Cu 0.7) |

|---|---|

| Flux type | MIL-RMA |

| Halide contents | 0.10%~0.14% |

| Powder particle size(μm) | 38~20(Type 4) |

| Flux contents(%) | 10.5% |

| Deterioration(Pa・S) | 230 |

| Copper plate corrosion test | No corrosion |

| Copper mirror corrosion | No corrosion |

| Insulation resistance(Ω) | More than 5.0×108Ω |

| Electrochemical migration | No migration |

| Flux name | 8229 |

Copyright © Ishikawa Metal Co.,LTD. All Rights Reserved.