M anagement System

anagement System

ISO 9001:2015

ISO 14001:2015

Marshallstraat 18c, 5705 CN Helmond

Tel:+31-655701610

soldersolutions@ishikawa-europe.com

Home > Lead-free (EVASOL) > [Solder paste (bottle)] Less void halogen free standard compliant type 7510 series

Adding material which faciliated that the gas in the molten solder comes out, it may reduce the remaining of voids.

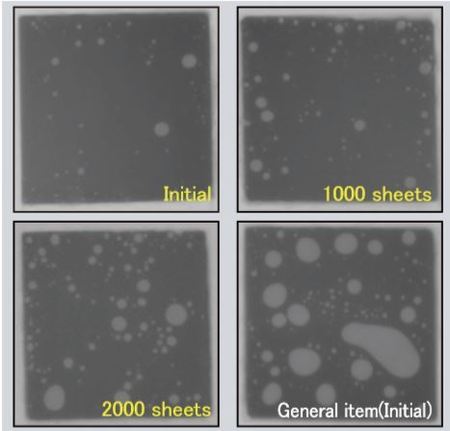

●Comparison of voids after continuous printing

Stable void reduction

No intentional addition of chlorine(Cl) bromine(Br), which generate dioxins.Compliant with most of halogen-free standards

●Compliant situation of 7510 series

| Standards | Compliant situation |

|---|---|

| JPCA-ES01 | Compliant |

| IEC61249-2-21 | Compliant |

| IPC4101B | Compliant |

| JEITA ET-7304A | Non Compliant |

Comply to all of halogen free standards

Higher heat resistance can reduce defect of non-wetting and non-melting

●Confirmation of wettability by reflow

Less void in large parts

Condition:Atmospheric

Pre heat:180℃,120 seconds

Component:6mm■ parts

| Alloy type | J3 (Sn:Bal / Ag 3.0 / Cu 0.5) |

|---|---|

| Flux type | Halogen free |

| Halide contents | Less than 0.01% |

| Powder particle size(μm) | 38~20(Type 4) |

| Flux contents(%) | 11.5% |

| Deterioration(Pa・S) | 180 |

| Copper plate corrosion test | No corrosion |

| Copper mirror corrosion | No corrosion |

| Insulation resistance(Ω) | More than 1.0×108Ω |

| Electrochemical migration | No migration |

| Halogen contents(ppm) | Cl : Less than 50 Br : Less than 100 |

| Flux name | 7510 |

Copyright © Ishikawa Metal Co.,LTD. All Rights Reserved.