M anagement System

anagement System

ISO 9001:2015

ISO 14001:2015

Marshallstraat 18c, 5705 CN Helmond

Tel:+31-655701610

soldersolutions@ishikawa-europe.com

Home > Lead-free (EVASOL) > [Solder paste (bottle)] Halogen free less spattering type 8850 series

The special activater enables to use low-Ag alloy.Achieves both of halogen-free and cost reduction.

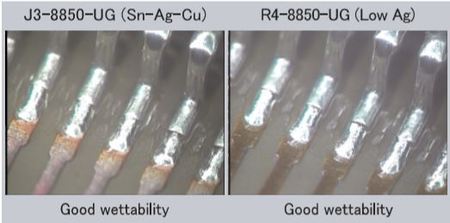

●High temperature preheating test

Low Ag alloy has euivalent wettability to 3Ag

Condition:Atmospheric

Component:QFP

0.5mm pitch

Easily applicable to low Ag for the improved heat resistance of the flux.It may help to reduce the cost.

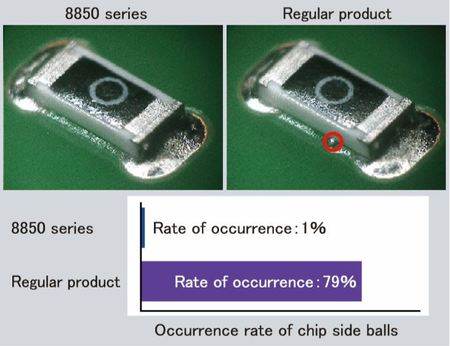

●Chip side ball test after reflow(3216 chip)

Reduce the chip side ball, ensure the good SMT quality

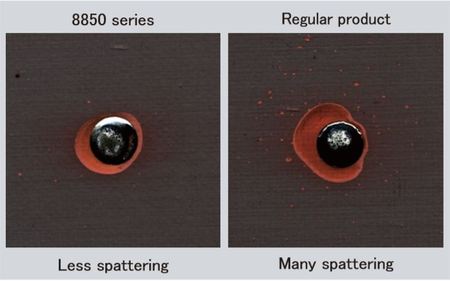

Selecting proper activator achieved less flux spattering during reflow soldering

●Spattering test with reflow

Stable shape after long time printing

J3-1001-UG(3Ag)

0.4mm pitch QFP

Stencil thickness:0.12mm

| Alloy type | J3 (Sn:Bal / Ag 3.0 / Cu 0.5) R4 (Sn:Bal / Ag 0.3 / Cu 0.7) |

|---|---|

| Flux type | Halogen free |

| Halide contents | Less than 0.02% |

| Powder particle size(μm) | 38~20(Type 4) |

| Flux contents(%) | 11.5% |

| Deterioration(Pa・S) | 190 |

| Copper plate corrosion test | No corrosion |

| Copper mirror corrosion | No corrosion |

| Insulation resistance(Ω) | More than 5.0×108Ω |

| Electrochemical migration | No migration |

| Halogen contents(ppm) | Cl : Less than 900 Br : Less than 900 |

| Flux name | 8850 |

Copyright © Ishikawa Metal Co.,LTD. All Rights Reserved.