M anagement System

anagement System

ISO 9001:2015

ISO 14001:2015

Marshallstraat 18c, 5705 CN Helmond

Tel:+31-655701610

soldersolutions@ishikawa-europe.com

Home > Technology > [Soldering issues] Flux spattering, solder ball (Flux cored solder wire)

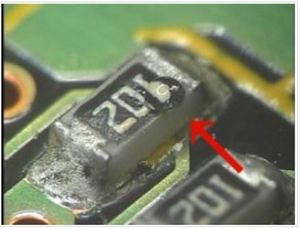

The flux spattering is a most problem in soldering with flux cored solder wire. The appearance of the product will be impaired. In addition, flux adhered to the liquid crystal screen, camera unit, switch contact point leads to defects in the product.

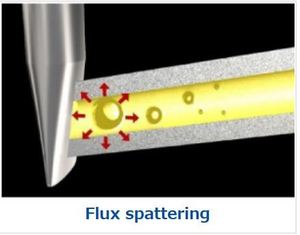

Flux spattering occurs when the low boiling point and low decomposition point components in the flux are boiled and gasified by the heat during soldering and exploded simultaneously with melting of the solder.

Factors that flux spattering is likely to occur are as follows.

· Not selected suitable solder for the work

· Too high iron temperature

· Too fast solder supplying

· High work area altitude (low ambient pressure)

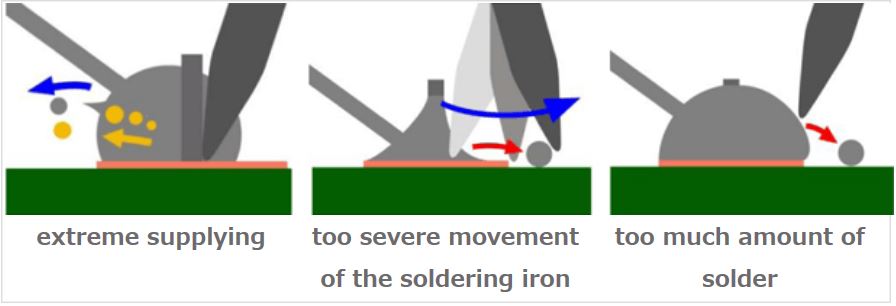

Solder ball easily occurs at the same time as flux spattering. Generated accompanying the flux spattering in extreme supplying, too severe movement of the soldering iron, even too much amount of solder.

It is possible to reduce the spattering by solder material, by increasing the melt viscosity of flux, using materials with less gasification, etc.

At our company

· Manual soldering

· LASER soldering

· Robot soldering

· High altitude (high altitude place, low atmospheric pressure place)

We have low spattering type flux cored solder wire suitable for each and please contact us.

Copyright © Ishikawa Metal Co.,LTD. All Rights Reserved.