M anagement System

anagement System

ISO 9001:2015

ISO 14001:2015

Marshallstraat 18c, 5705 CN Helmond

Tel:+31-655701610

soldersolutions@ishikawa-europe.com

Home > Technology > [Special usage] Low Ag solder · no Ag solder

The most widely used lead-free solder is Sn-3.0Ag-0.5Cu, which contains 3% Ag.

Ag, which is a precious metal, is expensive and price fluctuations are intense, so we have high risk of material cost and cost fluctuation in packaging.

Low Ag solder (reduced Ag content), and no Ag solder (not using Ag) are being introduced for this reason.

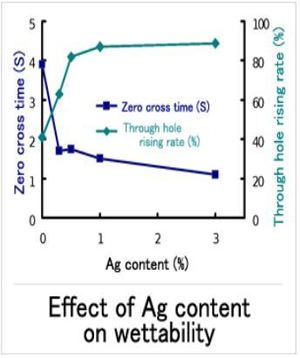

Ag in the solder has the role of lowering the melting point of the alloy, improving the wettability, increasing the mechanical strength, fatigue strength, creep strength, and so on. For this reason, there are packages that can be used with low-Ag solder and packages that are not applicable, and we need to proceed with the introduction taking this into account.

The packaging that can be introduced with low Ag and no Ag has the following features.

■Parts with large dimensions and large solder amount

TV · home appliances, LED lighting, battery pack

■Stress-free parts are soldered after mounting

Coil part of the motor (no stress occurs as the coil bends)

Since low Ag and no Ag solder contain a small amount of Ag, wettability and workability of them are inferior to ones of Sn-3.0Ag-0.5Cu solder. However, complementing with sufficient wettability flux ensures performance close to that of Sn-3.0Ag-0.5Cu.

We have solder paste and flux cored solder wire, corresponding to low Ag, no Ag, so please contact us.

Copyright © Ishikawa Metal Co.,LTD. All Rights Reserved.